Nowadays, the leather processing industry contributes significantly to economic progress while also facing global environmental challenges in order to reduce pollution and chemical hazards. Close monitoring by pollution control authorities, combined with growing societal awareness, is increasing the pressure on the industry to adopt cleaner/ greener processes and technology.

The chemicals generally used in the leather making are based on petrochemical chemistry, due to the easy fossil raw materials availability and their high chemical stability. In order to protect the environment and labourers, EU has compiled BREF (Best Available Techniques Reference document) and IPPC UE 2008 Directive, highly endorsing the reduction of water consumption in leather processing and pushing for the identification of efficient and sustainable alternatives concerning the use of Non Hazardous Substances and more Eco- Friendly products, that can also guarantee a reduction in the Carbon Foot Print.

Taking this into consideration, GG Organics has developed a new range of biopolymer retanning agents which provide significant resolutions for sustainability and assist tanners to produce high-quality leathers with a low environmental footprint.

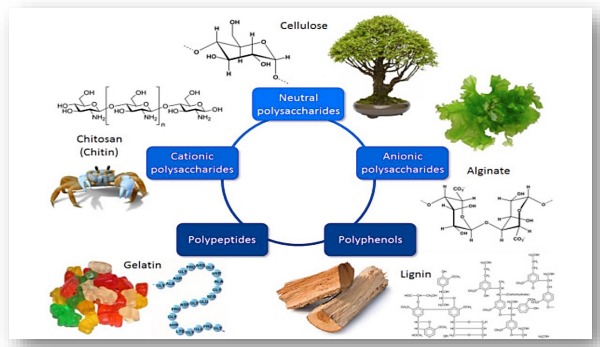

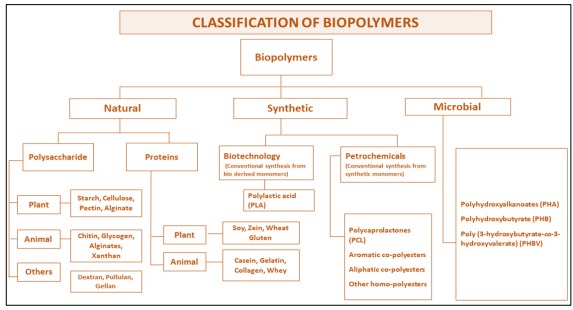

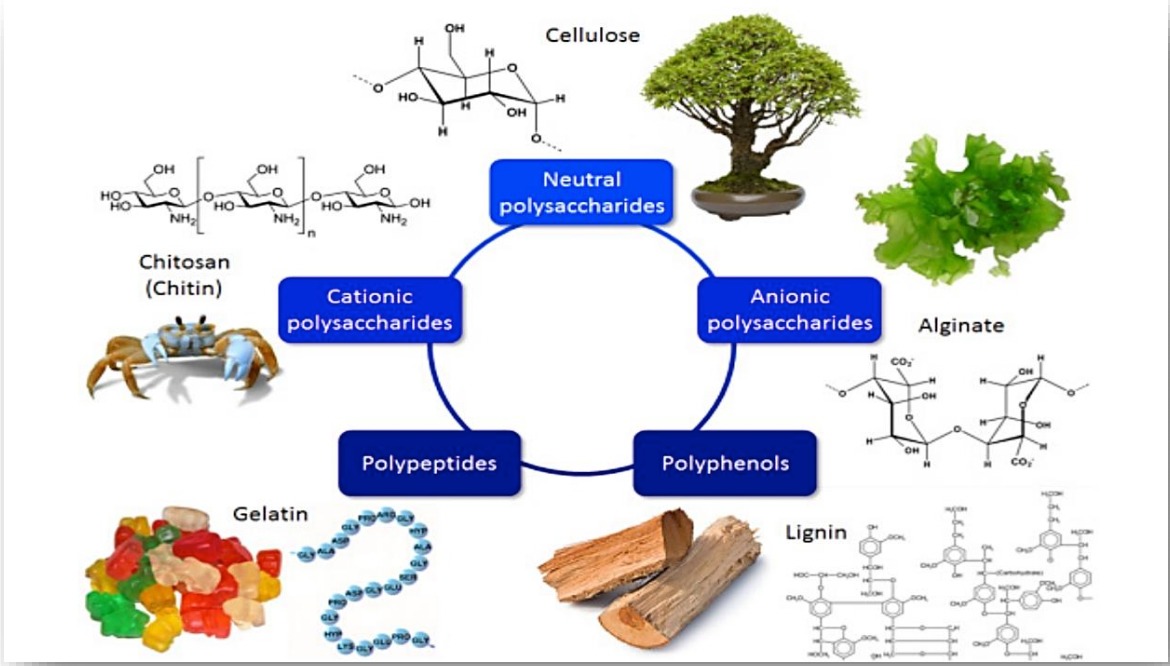

The following is a detailed description of the biopolymer and biodegradable;

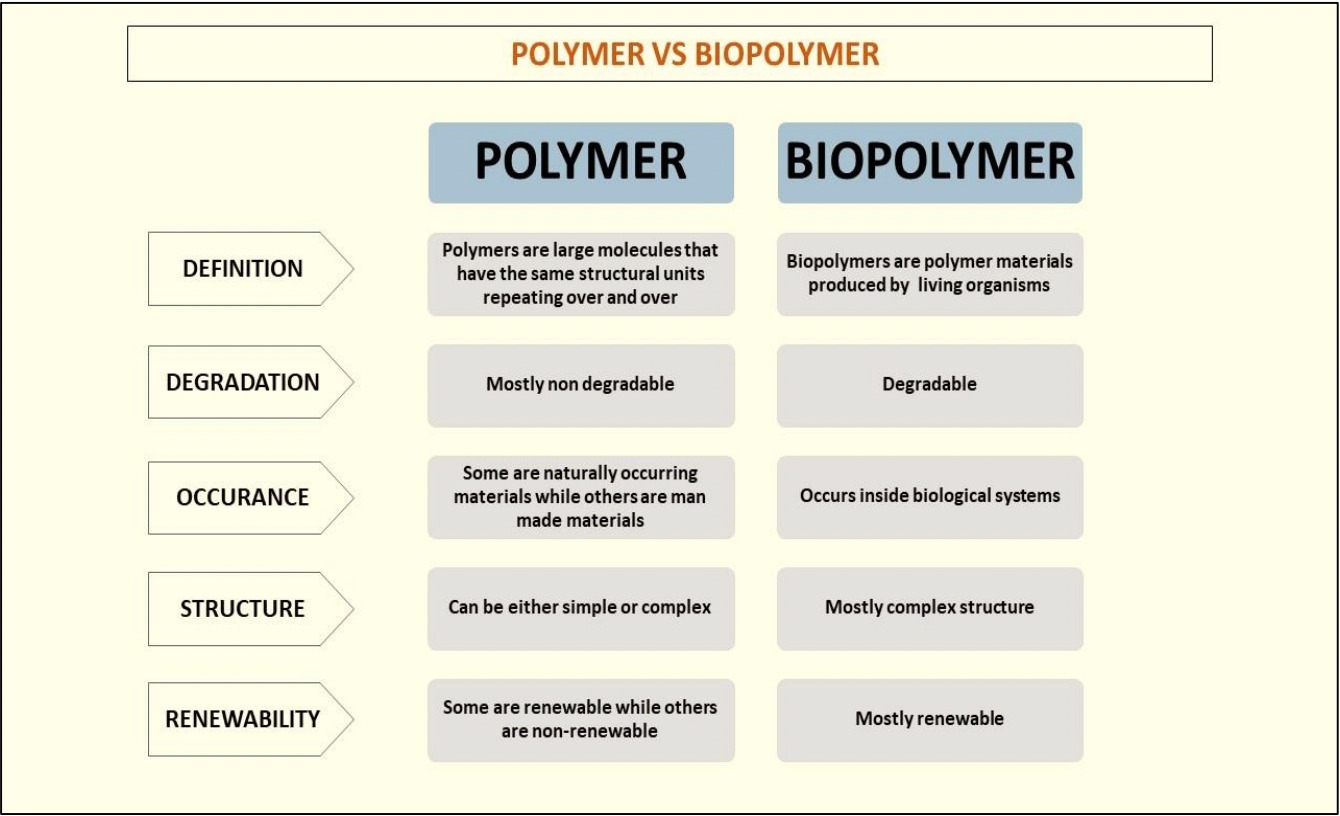

Biopolymers are polymers produced by living organisms; in other words, they are polymeric biomolecules.

Biopolymers cover a broad range of thermoplastics and thermosets, which are obtained either from renewable resources or from non-renewable resources such as petroleum. These polymers can be biodegradable and non-biodegradable depending on the chemical structure, nature of the polymer (i.e., crystalline or amorphous), molecular weight, and the environment.

Bio-based polymers include both naturally occurring polymers and synthetic polymers made from natural monomers. Bio-based polymers can potentially save fossil resources by using biomass that regenerates annually and contribute to advancing carbon neutrality, whereas biodegradability is an add-on property that offers an additional means of recovery at the end of a product’s life.

These polymers are carbon neutral and can always be renewed.

Reduce carbon dioxide levels in the atmosphere and also decrease carbon emissions.

These polymers are compostable which means there is less chance of environmental pollution.

These polymers are compostable, so there is less chance of environmental pollution.

Easily biodegradable and can decrease air pollution.

It greatly reduces the harmful effect of plastic use on the environment.

The leather industry generates a large amount of waste (Hair waste, Limed fleshings, shavings dust, and liquid waste containing the tanning agent) during the different stages of leather processing. These wastes are high in protein content (collagen, gelatine and keratin). Recent strategies demand a transition towards zero landfill and waste in leather production by reusing the leather waste as secondary raw material. To address the environmental concerns and to enhance the quality and biodegradability of leather, a range of biopolymers were developed using leather waste. Apart from that, it was developed due to

To meet the demand for eco-friendly and renewable biopolymers with high retanning characteristics

To replace hazardous and petroleum-based chemicals without altering the leather quality.

To enhance the recovery and reuse of bio-derived wastes and by-products from the leather and agro-industrial sector.

The leather industry makes extensive use of fossil fuel-based retanning agents, which are more hazardous to the environment. As a result, the industry is under pressure to innovate with more sustainable product

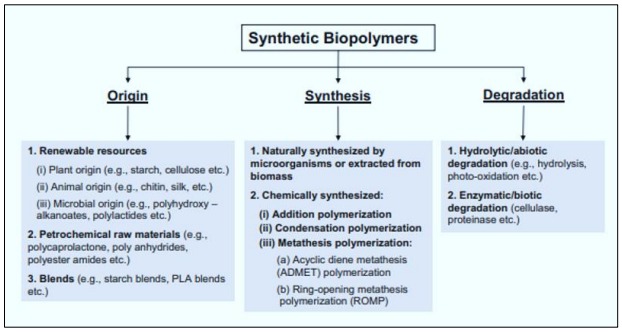

Synthetic biopolymers are derived from natural polymers or chemically synthesised from synthetic monomers in such a way that they degrade naturally without leaving any residues that are harmful to living organisms and natural environments. Regardless of the bio-based polymer, chemical synthesis is required for functionalization. The chemical synthesis process, in general, is known as polymerization

Synthetic biopolymers have received a lot of attention in recent years because of their distinct advantages over natural polymers in terms of stability and flexibility to suit a wide range of applications. Synthetic biopolymers are preferred over synthetic polymers due to their biodegradability and environmental friendliness.

Much required in the future as they are solution to green and sustainable environment Much will be required in the future as they are solutions to a green and sustainable environment.

They are biodegradable, and renewable and their production emit fewer greenhouse gases.

Reduce people dependence on fossil fuels

Slowly replacing the conventional polymers

It is used in a variety of industries including medicine, electronics, agriculture, leather, and automobiles.

It is projected that biodegradable biopolymers will constitute a larger percentage of biopolymer production in the coming years.

It has good compatibility with syntans, vegetable tannins, fat liquors and anionic dyestuffs.

Well suited for making all types of shoe uppers, upholstery and bag leathers

Download